Digital printing machine, ink savings coup!!!

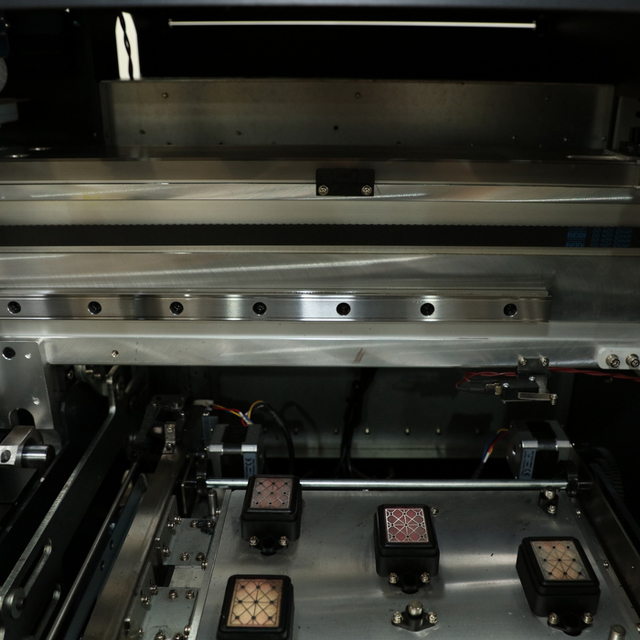

Digital printing machine in the digital printing industry has become increasingly widespread application of the printing industry has also brought unprecedented changes.

As we all know, inkjet technology is relatively more "squeamish", but also in the use of "quite stress."

So how to make it efficient for the printing industry, which has become the printing industry's top priority.

Today we will introduce the recipe for saving ink, to share with you here.

Try to focus on printing!

When using a piezoelectric digital printing machine, it is best not to print it every few minutes. If you need to print a lot of things, we suggested that the need to print things together to focus on printing.

Every time the machine is started, the print head and the printer are cleaned, and the ink delivery system is filled with ink. This process wastes more ink, so try not to start the machine as often as possible.

Clean the print head correctly!

Most inkjet printing devices will automatically clean the print head and have a button to clean the print head. If the device's automatic cleaning function is invalid, the print head can be manually cleaned.

Manual cleaning should remove the printhead as described in the operating manual. Manual cleaning of the print head can be in the front of the medical syringe cover a fine tube, into the strict filtered water rinse, rinse with a magnifying glass to carefully observe the nozzle, such as spray hole next to the silt residue, can be used to remove the soft plastic products.

Long time to put on the integration of the print head as the ink dry and plug the nozzle, you can use hot water soaked and then cleaned.

Cleaning the printhead should note the following points

A, Do not use sharp objects cleaning nozzle, can not hit the nozzle, do not touch the nozzle;

B, Can not be disassembled in the live state, install the nozzle, do not hand or other items contact the nozzle on the electrical contacts;

C, Can not remove the nozzle from the printer alone placed, can not place the nozzle in dusty places.

Do not replace the ink cartridge immediately!

Digital printing equipment through the sensor sensor to detect the amount of ink in the cartridge, the sensor as long as the detection of one color ink is less than the value set within the printer, then prompted to replace the cartridge. At this point, we can remove the ink cartridge to reset the internal sensor of the printer to determine the installation of the new cartridge.

Try to minimize the number of cleaning!

Equipment in the use of the process often occurs inkjet plug phenomenon, causing a lot of clogging reasons, such as the machine's working environment, the quality of ink, the machine idle time and so on. Each time you wash the inkjet head to consume a lot of ink, so should try to reduce the number of cleaning inkjet head.

Of course, when using the machine should pay attention to the use of machine manufacturers specify the type of ink.

Nanjing Sub Textile Co., Ltd

web:www.subtextile.com

e-mail:[email protected]

Choose sublimation paper? Focus on quality over price

Choose sublimation paper? Focus on quality over price

7 Factors To Consider Before Choosing A Digital Textile Printer

7 Factors To Consider Before Choosing A Digital Textile Printer

2024 Apparel Decoration Industry Trends

2024 Apparel Decoration Industry Trends

What are the features of digital textile printing equipment

What are the features of digital textile printing equipment